Study the Tribology Characteristics of HDPE Reinforced by Al2O3 and CNTs

Main Article Content

Abstract

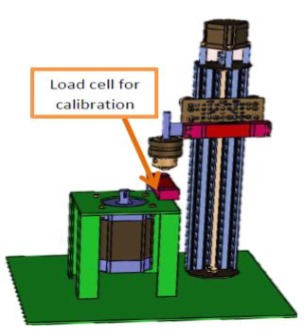

The current work focuses on design pin-on-disc tribometer using stepper motors and linear actuator to achieve better accuracy of results. also focuses on improving the tribological properties of high-density polyethylene (HDPE) reinforced by 0.1– 0.5 wt. % of Al2O3, 0.1– 0.5 wt% SWCNTs and 0.1– 0.5 wt% MWCNTs nanoparticles. The nano-composite specimens were prepared to the cylindrical shape and subjected to friction and wear tests using pin on disc tribometer. The specimens were tested as counterpart and the disk which made from stainless steel. Wear tests were done each exactly 120 sec., and the weight losses calculated by weighing the specimens before and after the test. It is very well noticed from the experiments that the HDPE nano-composite specimen of 0.2 wt% of Al2O3, 0.5wt% of SWCNTs and 0.2 wt% of MWCNTs gives the best tribological properties so that the friction coefficient is reduced also the wear rate.

Article Details

References

T. K. Goswami and S. Mangaraj, “Advances in polymeric materials for modified atmosphere packaging (MAP),” in Multifunctional and nanoreinforced polymers for food packaging, Elsevier, 2011, pp. 163–242.

R. A. Nabhan, A;, “Study of wear and friction behavior of HDPE-composite filled by CNTs,” KGK Kautschuk Gummi Kunststoffe, vol. 73, no. 9, pp. 27–38, 2020.

B. Tajeddin, B. Ahmadi, F. Sohrab, and H. A. Chenarbon, “Polymers for modified atmosphere packaging applications,” in Food Packaging and Preservation, Elsevier, 2018, pp. 457–499.

S. Xu and X. W. Tangpong, “Tribological behavior of polyethylene-based nanocomposites,” J. Mater. Sci., vol. 48, no. 2, pp. 578–597, 2013.

A. Rashed and A. Nabhan, “Influence of adding nano graphene and hybrid SiO2-TiO2 nano particles on tribological characteristics of polymethyl methacrylate (PMMA),” KGK-Kautschuk Gummi Kunststoffe, vol. 71, no. 11–12, pp. 32–37, 2018.

J. X. Chan et al., “Effect of nanofillers on tribological properties of polymer nanocomposites: A review on recent development,” Polymers (Basel)., vol. 13, no. 17, p. 2867, 2021.

N. P. Suh, M. Mosleh, and J. Arinez, “Tribology of polyethylene homocomposites,” Wear, vol. 214, no. 2, pp. 231–236, 1998.

J. Wu and Z. Peng, “Investigation of the geometries and surface topographies of UHMWPE wear particles,” Tribol. Int., vol. 66, pp. 208–218, 2013.

S. Sahebian, S. M. Zebarjad, S. A. Sajjadi, Z. Sherafat, and A. Lazzeri, “Effect of both uncoated and coated calcium carbonate on fracture toughness of HDPE/CaCO3 nanocomposites,” J. Appl. Polym. Sci., vol. 104, no. 6, pp. 3688–3694, 2007.

A. Chafidz, I. Ali, M. E. Ali Mohsin, R. Elleithy, and S. Al-Zahrani, “Atomic force microscopy, thermal, viscoelastic and mechanical properties of HDPE/CaCO3 nanocomposites,” J. Polym. Res., vol. 19, no. 4, pp. 1–17, 2012.

A. Nabhan, A. K. Ameer, and A. Rashed, “Tribological and Mechanical Properties of HDPE Reinforced by Al2O3 Nanoparticles for Bearing Materials,” 2019.

S. Srivastava and D. Organisation, “Study of ultra high molecular weight polyethylene/HDPE/alumina nanocomposites and their characterization,” J Adv Res Poly Text Engi, vol. 4, no. 1, pp. 1–9, 2017.

N. Guermazi, K. Elleuch, H. F. Ayedi, V. Fridrici, and P. Kapsa, “Tribological behaviour of pipe coating in dry sliding contact with steel,” Mater. Des., vol. 30, no. 8, pp. 3094–3104, 2009.

H. Jemii, A. Boubakri, A. Bahri, D. Hammiche, K. Elleuch, and N. Guermazi, “Tribological behavior of virgin and aged polymeric pipes under dry sliding conditions against steel,” Tribol. Int., vol. 154, p. 106727, 2021.

J. C. Anderson, “High density and ultra-high molecular weight polyethenes: their wear properties and bearing applications,” Tribol. Int., vol. 15, no. 1, pp. 43–47, 1982.

J. M. Kelly, “Ultra-high molecular weight polyethylene,” J. Macromol. Sci. Part C Polym. Rev., vol. 42, no. 3, pp. 355–371, 2002.

S. M. Kurtz, UHMWPE biomaterials handbook: ultra high molecular weight polyethylene in total joint replacement and medical devices. Academic Press, 2009.

P. Bracco, A. Bellare, A. Bistolfi, and S. Affatato, “Ultra-high molecular weight polyethylene: influence of the chemical, physical and mechanical properties on the wear behavior. A review,” Materials (Basel)., vol. 10, no. 7, p. 791, 2017.

A. Fouly, A. Nabhan, and A. Badran, “Mechanical and Tribological Characteristics of PMMA Reinforced by Natural Materials,” Egypt. J. Chem., vol. 65, no. 4, pp. 1–2, 2022.

J. C. Baena, J. Wu, and Z. Peng, “Wear performance of UHMWPE and reinforced UHMWPE composites in arthroplasty applications: a review,” Lubricants, vol. 3, no. 2, pp. 413–436, 2015.

M. Taha, M. Hassan, M. Dewidare, M. A. Kamel, W. Y. Ali, and A. Dufresne, “Evaluation of eco-friendly cellulose and lignocellulose nanofibers from rice straw using Multiple Quality Index,” Egypt. J. Chem., vol. 64, no. 8, pp. 4707–4717, 2021.

N. El-Wakil, M. Taha, and R. Abouzeid, “Dissolution and regeneration of cellulose from N-methylmorpholine N-oxide and fabrication of nanofibrillated cellulose,” Biomass Convers. Biorefinery, pp. 1–12, 2022.

Eyad M. A.; Ali W. Y.; Nabhan A., “Wear Behavior of Cervical Fusion Plates Fabricated from Polyethylene Reinforced by Kevlar and Carbon Fibers,” EGTRIB J., vol. 18, no. 1, pp. 8–17, 2021.

L. I. Havelin et al., “The Nordic Arthroplasty Register Association: a unique collaboration between 3 national hip arthroplasty registries with 280,201 THRs,” Acta Orthop., vol. 80, no. 4, pp. 393–401, 2009.

A. Fouly, A. M. M. Ibrahim, E.-S. M. Sherif, A. MR FathEl-Bab, and A. H. Badran, “Effect of Low Hydroxyapatite Loading Fraction on the Mechanical and Tribological Characteristics of Poly (Methyl Methacrylate) Nanocomposites for Dentures,” Polymers (Basel)., vol. 13, no. 6, p. 857, 2021.

M. Gallab, M. Taha, A. Rashed, and A. Nabhan, “Effect of Low Content of Al2O3 Nanoparticles on the Mechanical and Tribological Properties of Polymethyl Methacrylate as a Denture Base Material,” Egypt. J. Chem., 2022.

N. Shahemi, S. Liza, A. A. Abbas, and A. M. Merican, “Long-term wear failure analysis of uhmwpe acetabular cup in total hip replacement,” J. Mech. Behav. Biomed. Mater., vol. 87, pp. 1–9, 2018.

A. K. Ameer, M. O. Mousa, and W. Y. Ali, “Tribological Behaviour of Poly-methyl Methacrylate reinforced by Multi-Walled Carbon Nanotubes,” KGK-KAUTSCHUK GUMMI KUNSTSTOFFE, vol. 71, no. 10, pp. 40–46, 2018.

A. Meshref, A. Mazen, M. El-Giushi, and W. Ali, “EGTRIB Journal,” J. Egypt. Soc. Tribol., vol. 13, no. 2, pp. 25–37, 2016.

A. AK, M. MO, A. WY, S. AM, and E.-A. AH, “Influence of Counterface Materials on the Tribological Behavior of Dental Polymethyl Methacrylate Reinforced by Single-Walled Carbon Nanotubes (SWCNT),” SVU-International J. Eng. Sci. Appl., vol. 3, no. 2, pp. 68–79, 2022.

A. K. Ameer, M. O. Mousa, and W. Y. Ali, “Hardness and wear of polymethyl methacrylate filled with multi-walled carbon nanotubes as denture base materials,” J. Egypt. Soc. Tribol., vol. 14, no. 3, pp. 66–83, 2017.

V. I. Pakhaliuk, V. N. Vasilets, A. M. Poliakov, and N. A. Torkhov, “Reducing the Wear of the UHMWPE Used in the Total Hip Replacement after Low-Pressure Plasma Treatment,” J. Appl. Comput. Mech., vol. 8, no. 3 (In Progress), pp. 1035–1042, 2022.

H. Oonishi, M. Kuno, E. Tsuji, and A. Fujisawa, “The optimum dose of gamma radiation–heavy doses to low wear polyethylene in total hip prostheses,” J. Mater. Sci. Mater. Med., vol. 8, no. 1, pp. 11–18, 1997.